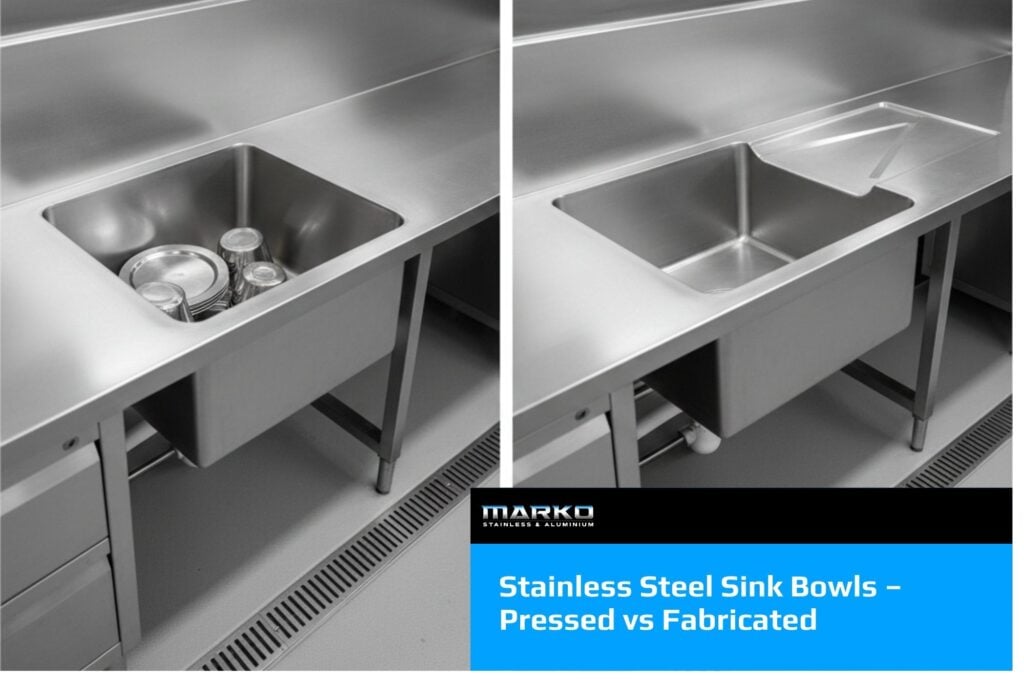

When you are specifying a stainless steel sink, the bowl is the workhorse. It handles heat, knocks, chemicals, daily clean-downs, and constant traffic. Yet one of the biggest decisions is often overlooked: do you choose a pressed sink bowl or a fabricated stainless steel sink bowl?

Both options can be excellent, but they suit different applications, budgets, and performance expectations. At Marko Stainless & Aluminium, we work with builders, architects and schools to supply the right stainless sink solution for the job. We also fabricate custom bowls when a standard option will not deliver the finish, size, or durability your project needs.

What is a Pressed Sink Bowl

A pressed stainless sink bowl is formed by pressing a sheet of stainless steel into a die to create the bowl shape. This is common in standard kitchen sinks and many off the shelf commercial sink products.

Key characteristics of pressed sink bowls:

- Generally available in standard sizes and depths

- Typically quicker to source and often lower upfront cost

- Smooth, consistent shape from mass production

- Suitable where a standard bowl size fits the design

Pressed bowls are a practical option when you need a reliable stainless sink at a competitive price and the project does not require custom sizing or special detailing.

What is a Fabricated Stainless Steel Sink Bowl

A fabricated sink bowl is made by cutting stainless sheet to size, forming panels, then welding the seams to create a bowl. The welds are then finished and polished to create a clean, hygienic result.

Key characteristics of fabricated sink bowls:

- Custom sizes, depths and shapes, including oversized bowls

- Can be designed to suit specific equipment, workflows, and clearances

- Strong construction suited to heavy-use environments

- Seam finishing can deliver a premium, professional appearance

Fabricated bowls are a go-to choice for commercial kitchens, food production facilities, labs, schools, and any site where standard bowls do not suit the layout or performance requirements.

Pressed vs Fabricated, the Real World Differences

Here is how pressed and fabricated stainless sink bowls compare in the areas that matter most on site.

1) Size and Fit

Pressed bowls come in set sizes. If the bench opening, cabinet layout, or plumbing positions do not match, you can quickly lose time making compromises.

Fabricated bowls allow true made to measure sinks. This is especially valuable for:

- Long or deep benches where a standard bowl looks undersized

- Tight plant rooms or staff amenities with awkward layouts

- Multi bowl stations where workflow matters, such as wash, rinse, sanitise

- Education and commercial projects where drawings demand exact dimensions

2) Strength and Durability

Pressed bowls can be strong, but strength varies by bowl design and material thickness. In demanding environments such as commercial kitchens, school canteens, and public amenities, heavy impacts and daily cleaning are the norm.

Fabricated bowls can be specified for heavier duty performance because the fabrication process supports different thicknesses and reinforcement where needed. The result is a stainless sink bowl built for a long service life.

3) Hygiene and Cleanability

Stainless is chosen because it is non porous and easy to sanitise. With pressed bowls, the smooth shape is a plus, but overall hygiene performance comes down to how the bowl integrates with the benchtop and how edges and joins are finished.

Fabricated bowls can be integrated into stainless benches and benchtops for a seamless look and practical cleaning access. When welds are finished correctly, the result is a hygienic, easy clean surface that suits high use environments.

4) Design and Aesthetics

Pressed bowls are predictable, which is ideal if you want a simple, standard look.

Fabricated bowls are best when design intent matters. You can specify tighter corner radii, exact depths, matching drainboard layouts, and a cohesive fitout appearance. For architects and builders aiming for a premium finish, fabricated bowls can lift the whole space.

5) Lead Times and Project Coordination

Pressed bowls are often sourced as standard products, which can be fast unless the project needs a non standard size or the supplier has stock delays.

Fabricated bowls allow local control. When you are coordinating benches, splashbacks, sinks, and other stainless components, custom fabrication can reduce the risk of fit issues that cause rework and delays.

Where Pressed Bowls Make Sense

A pressed stainless sink bowl is often the right option for:

- Projects with standard cabinetry and standard sink cut outs

- Fitouts where budget is the primary driver

- Sites with lower traffic and lower impact risk

- Situations where available pressed sizes suit the design perfectly

Where Fabricated Bowls Win

A fabricated stainless steel sink bowl is often the best choice for:

- Commercial kitchens and food service areas

- Schools and high traffic amenities

- Labs and specialist rooms where durability and hygiene matter

- Custom stainless benches with integrated sinks

- Projects needing specific depths, unusual lengths, or multiple bowl layouts

Choosing the Right Stainless Steel Sink Bowl for Your Project

When comparing pressed versus fabricated sink bowls, ask three practical questions:

- Does a standard bowl size fit the space and plumbing layout without compromise

- How hard will the sink be used, including daily traffic, impact risk, and cleaning intensity

- Do you need a coordinated stainless package, bench plus bowl plus splashback, to reduce installation issues

If your answers point toward custom sizing, heavy use, or coordinated fitouts, fabricated bowls are often the smarter long term option.

Why Choose Marko Stainless & Aluminium

- Detail first fabrication: We build to drawings and critical dimensions so sinks, benches and splashbacks align cleanly on site

- Custom made to measure solutions: Fabricated sink bowls can be designed around workflow, clearances and real world use

- Quality you can specify with confidence: As an ASSDA accredited fabricator, we focus on workmanship, finish and long term durability

- Australian made capability: Local fabrication supports consistency, communication, and project coordination

- Trading since 1994: Proven experience supporting schools, builders and architects across Australia

Conclusion

Pressed sink bowls and fabricated stainless steel sink bowls both have a place, but the best choice depends on the job.

If you need a standard solution at a sharp price, pressed bowls can be a great fit. If you need exact sizing, heavier duty performance, or a fully coordinated stainless fitout, fabricated bowls deliver the flexibility and durability that high use environments demand.

Call to Action

Contact Marko Stainless & Aluminium to discuss the right stainless steel sink bowl for your project, whether you need a standard pressed bowl or a custom fabricated solution built to suit your site.