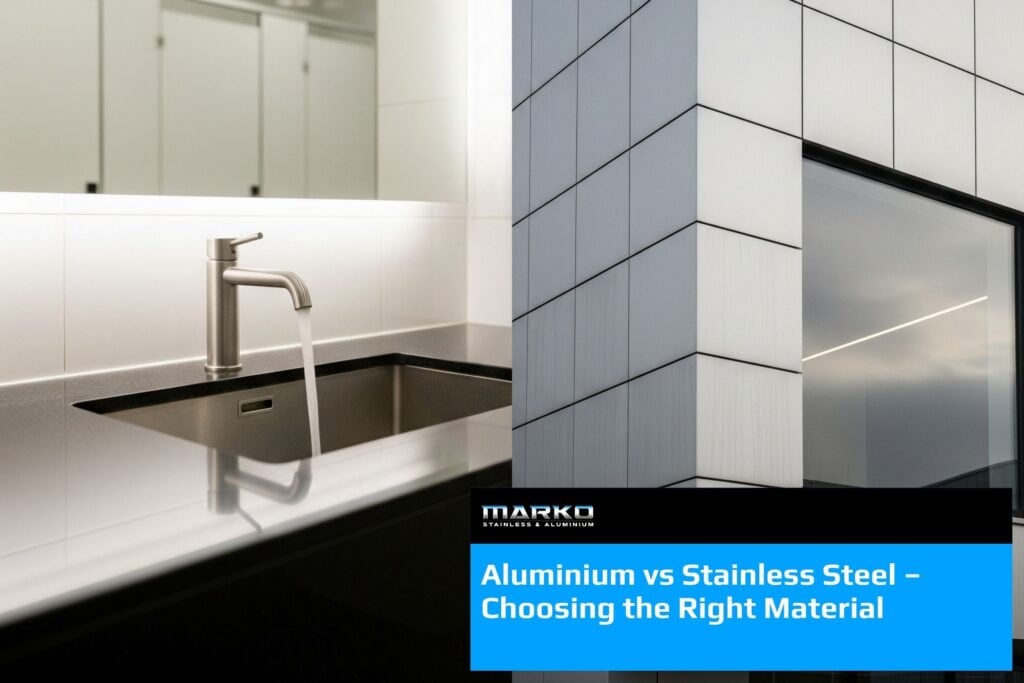

When it comes to modern construction and architectural projects, material selection is critical. Two of the most common metals specified are stainless steel and aluminium. While they may seem similar at first glance, each offers distinct benefits that make it more suitable for certain applications. At Marko Stainless, we fabricate with both stainless steel and aluminium, which means we can provide unbiased advice to help builders, architects, and schools make the right decision.

In this article, we’ll break down the differences between stainless steel and aluminium, exploring strength, cost, appearance, and common applications — so you can be confident in your choice.

Strength and Durability

One of the key differences between stainless and aluminium lies in strength.

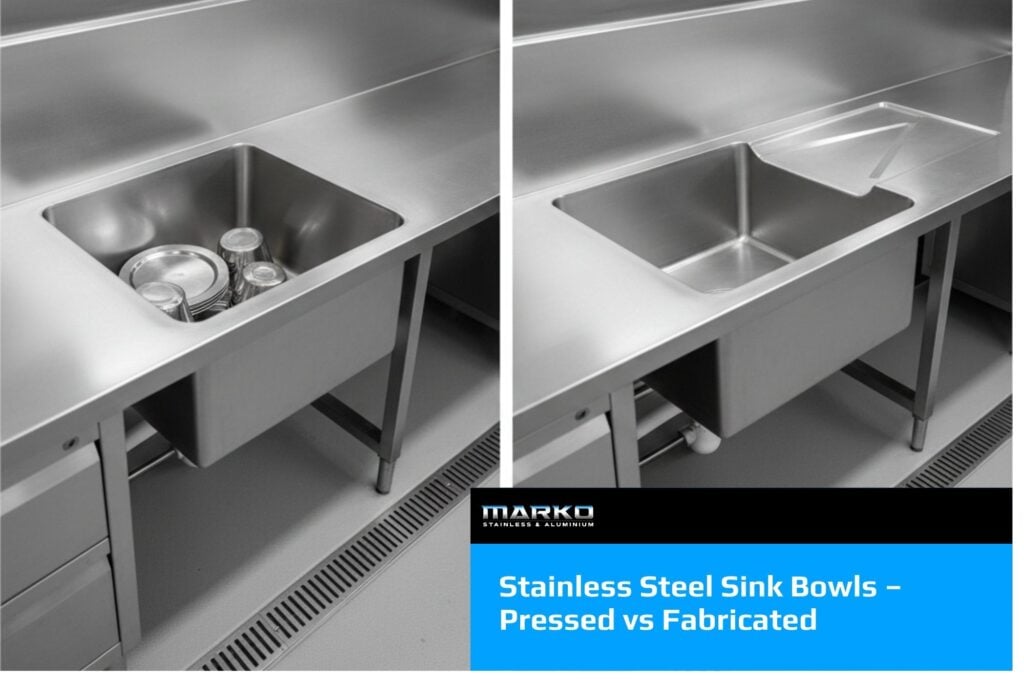

- Stainless steel is much stronger and more impact-resistant than aluminium. This makes it ideal for applications where fixtures will face constant use and possible abuse — for example, stainless wash troughs, stainless sinks, stainless benchtops, and public amenities such as urinals and mirrors. Stainless is also far less prone to denting.

- Aluminium, on the other hand, is valued for its lightweight properties. While it doesn’t have the same tensile strength as stainless, it’s still durable enough for external structures, aluminium window hoods, cladding, and architectural shading systems. Its reduced weight also makes it easier to install in certain contexts.

Corrosion Resistance

Both metals are resistant to corrosion, but in different ways.

- Stainless steel is naturally resistant to rust and corrosion due to its chromium content. Grade 316 stainless, in particular, is highly resistant to saltwater and chemicals, making it suitable for harsh environments like coastal schools or commercial kitchens.

- Aluminium develops a natural oxide layer when exposed to air, which protects it from corrosion. However, aluminium can suffer from galvanic corrosion if it comes into contact with other metals, and it isn’t as chemically resistant as stainless.

Weight and Handling

- Aluminium is about one-third the weight of stainless steel. This makes it easier to transport, handle, and install, particularly on large projects or where structural weight is a consideration. For example, architects may prefer aluminium for suspended shading devices or façade elements.

- Stainless steel, while heavier, provides robustness that’s unmatched in heavy-use fixtures. For items like wash troughs or benchtops, the additional weight ensures stability and long-term durability.

Cost Considerations

Generally, aluminium is less expensive per kilogram than stainless steel. However, when life-cycle costs are considered, stainless often wins out in applications requiring hygiene, long-term strength, and corrosion resistance.

For example, an aluminium trough may initially cost less, but a stainless wash trough will last longer, require less maintenance, and deliver better hygiene outcomes, making it more cost-effective over time.

Aesthetic Appeal

Both materials offer a sleek, modern look, but with subtle differences:

- Stainless steel has a reflective, polished appearance that pairs well with contemporary design. It conveys cleanliness and professionalism, which is why stainless benchtops and stainless sinks are a staple in hospitality and healthcare.

- Aluminium has a softer, matte finish that architects often specify for external design elements. Powder-coating or anodising can also provide a wide range of colours, adding flexibility to its aesthetic use.

Applications of Stainless Steel

- School washrooms: stainless steel wash troughs, urinals, and mirrors

- Commercial kitchens: stainless steel benchtops and sinks

- Science labs and healthcare: corrosion-resistant fixtures

- Public amenities: vandal-resistant and easy-to-clean surfaces

Applications of Aluminium

- Aluminium window hoods for shading and energy efficiency

- Building façades and cladding

- Lightweight architectural features

- Outdoor furniture and fixtures in non-heavy traffic areas

Compliance and Accreditation

For schools and public projects, compliance is crucial. Stainless steel fittings from Marko Stainless are EFSG compliant and fabricated by an ASSDA accredited team, ensuring the highest quality standards. Aluminium products, while not covered under EFSG, are fabricated to meet Australian building standards and tailored for architectural performance.

Conclusion

Both stainless steel and aluminium have important roles to play in modern construction and design. Stainless offers strength, hygiene, and compliance, making it the go-to for washrooms, benchtops, and sinks. Aluminium provides lightweight versatility and design flexibility, ideal for external shading and façades.

By working with a fabricator like Marko Stainless, you gain access to both capabilities — ensuring the right material is used for the right application.

Contact Marko Stainless today to discuss your stainless steel and aluminium fabrication needs. We’ll help you choose the best solution for your project.