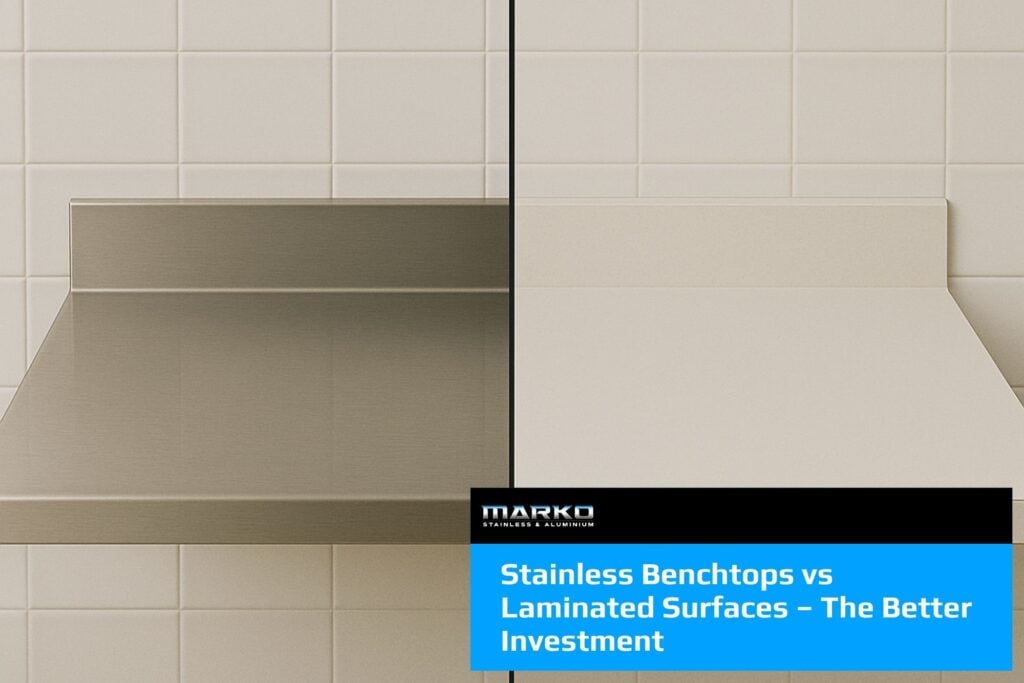

When it comes to choosing benchtop materials, two options often stand out: stainless steel benchtops and laminated surfaces. While laminate may seem appealing due to its lower upfront cost and wide range of colours, stainless steel offers unmatched durability, hygiene, and long-term value.

At Marko Stainless, we’ve been fabricating custom stainless benchtops for schools, commercial kitchens, and laboratories since 1994. In this blog, we’ll compare stainless with laminate to help builders, architects, and schools make informed decisions.

Stainless Steel Benchtops – Built for Performance

A stainless steel benchtop is more than just a work surface — it’s a long-term investment in durability and hygiene.

Key Advantages of Stainless Benchtops:

- Hygienic: Non-porous surface resists bacteria and is easy to clean.

- Durable: Resistant to heat, impact, and corrosion.

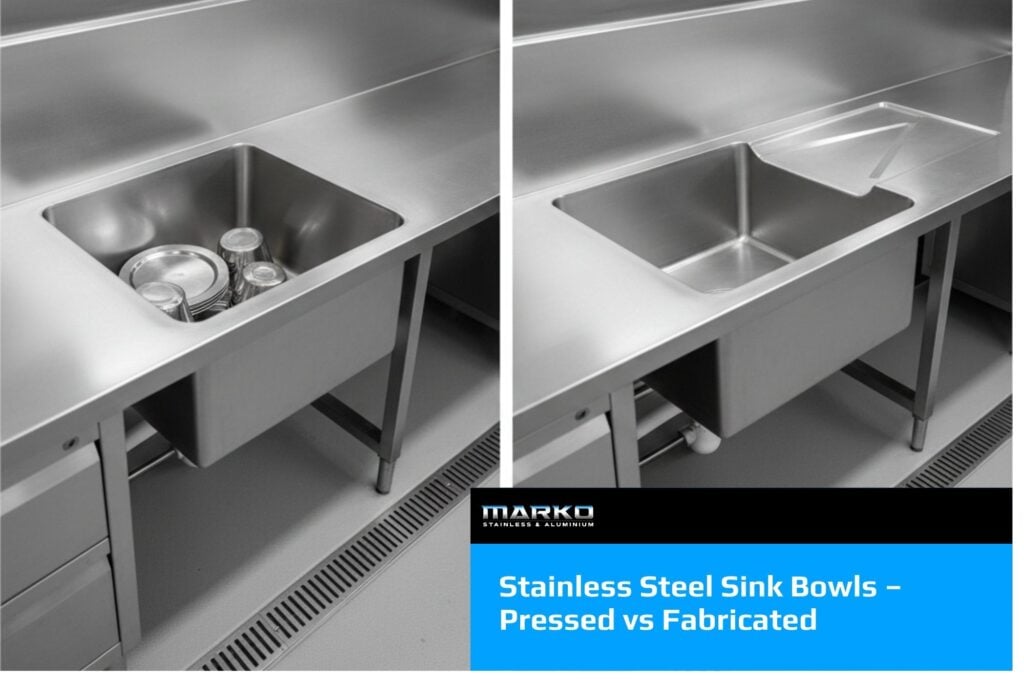

- Customisable: Can be fabricated with integrated sinks, splashbacks, and drainers.

- Sustainable: Fully recyclable and long-lasting, reducing waste.

For schools, hospitality, and healthcare environments, stainless benchtops are the gold standard.

Laminated Surfaces – The Budget Option

Laminated surfaces are made by bonding decorative sheets to particleboard or MDF. They’re widely used in residential kitchens and offices because they’re affordable and available in many finishes.

Advantages of Laminated Surfaces:

- Lower initial cost

- Wide range of colours and textures

- Easy to install in low-use environments

However, in high-traffic or high-moisture environments, laminated surfaces quickly reveal their limitations.

Comparing Durability

- Heat Resistance: Stainless steel handles hot pots and equipment without damage. Laminate can scorch or bubble when exposed to heat.

- Moisture Resistance: Stainless is corrosion-proof. Laminate, built on particleboard or MDF, swells and warps when exposed to water.

- Impact Resistance: Stainless withstands heavy impacts. Laminate chips and cracks easily under pressure.

In schools, commercial kitchens, and labs, these differences make stainless steel the clear winner.

Hygiene and Maintenance

In environments where hygiene is critical, such as food tech classrooms, commercial kitchens, or hospitals, stainless steel is unmatched. It provides a smooth, non-porous surface that prevents bacteria growth and can be sanitised easily.

Laminated surfaces, on the other hand, have seams and joints that can trap dirt and bacteria. Once the laminate is damaged, it’s difficult to clean and maintain, often leading to replacement.

Cost Over the Product Life

While laminate is cheaper upfront, the long-term cost of repairs and replacements often outweighs the initial savings. A stainless benchtop, though more expensive to purchase, offers:

- Decades of service life

- Minimal maintenance costs

- Fewer replacements over time

For schools and businesses with tight budgets, stainless steel proves to be the more cost-effective solution over the life of the product.

Customisation and Design

At Marko Stainless, we fabricate custom stainless benchtops to meet project requirements, including:

- Integrated sinks and drainers

- Splashbacks for wall protection

- Polished or brushed finishes

- Sizes tailored to fit any space

This flexibility ensures stainless benchtops work in classrooms, science labs, hospitality kitchens, and healthcare environments. Laminate, while available in many colours, cannot match stainless steel’s ability to be custom-fabricated into seamless, hygienic workstations.

Why Stainless Benchtops Are the Better Investment

When comparing stainless benchtops vs laminated surfaces, the choice comes down to priorities:

- If the project is short-term, low-use, and budget-driven, laminate may suffice.

- For long-term durability, hygiene, and compliance, stainless benchtops are the smarter investment.

For schools, commercial kitchens, and healthcare projects, stainless steel is the material that meets compliance, hygiene, and performance requirements without compromise.

Why Choose Marko Stainless?

- Over 30 years of experience fabricating custom stainless benchtops

- ASSDA accredited fabricator ensuring industry-leading quality

- EFSG compliant stainless products for schools

- Australian-made, designed for local conditions

- Trusted supplier to builders, architects, and plumbing wholesalers

Conclusion

While laminated surfaces may appear cheaper upfront, stainless steel benchtops deliver far greater value over time. With unmatched durability, hygiene, and design flexibility, stainless steel is the best choice for schools, kitchens, and high-traffic environments.

Contact Marko Stainless today to request a quote on stainless steel benchtops for your next project.